Food Safety Software Buyer’s Guide: What to Look for in a Modern Compliance Platform

What is Food Safety Software and Why Do Food Businesses Need It?

Food safety software is a digital compliance platform designed to help food businesses manage regulatory requirements, monitor critical control points, and document food handling processes. These systems replace traditional paper-based methods with automated tracking, real-time alerts, and centralized data management that ensures businesses meet standards set by regulatory bodies like the FDA, USDA, and local health departments.

Why Food Businesses Need Food Safety Software

Modern food businesses face mounting pressure to demonstrate compliance across every stage of production and distribution. A robust food safety compliance platform addresses this challenge by:

- Preventing costly violations through automated monitoring of critical control points and instant deviation alerts

- Protecting brand reputation by reducing the risk of contamination incidents and product recalls

- Streamlining documentation for audits and inspections with electronic record-keeping

- Ensuring traceability from raw materials through finished products

The stakes are particularly high in today’s food industry. A single compliance failure can result in regulatory penalties exceeding hundreds of thousands of dollars, not to mention the devastating impact of foodborne illness outbreaks on consumer trust. Food safety software transforms compliance from a reactive, paper-intensive burden into a proactive system that safeguards both public health and business continuity.

What Are the Core Challenges Food Businesses Face in Compliance Management?

Food businesses face several challenges when it comes to managing compliance:

- Regulatory Requirements: Regulatory requirements change frequently across different jurisdictions, making it difficult for food businesses to maintain consistent compliance. The FDA, USDA, and international bodies regularly update standards, requiring constant vigilance and adaptation from food manufacturers and distributors.

- Non-Compliance Consequences: Non-compliance can result in severe consequences such as financial penalties, product recalls, legal liability, damage to brand reputation, and potential facility shutdowns.

- Food Safety Risks: Manual and paper-based systems create additional food safety risks due to human error and inefficiency. Staff members must physically record temperatures, document cleaning schedules, and maintain logs across multiple locations, which can lead to mistakes and gaps in compliance.

- Lack of Real-Time Visibility: Paper systems do not provide real-time visibility into compliance status, making it difficult for management to identify gaps or respond to emerging issues quickly.

- Time-Consuming Documentation Retrieval: When auditors request documentation, teams often waste hours searching through filing cabinets and binders for paper records.

- Unmonitored Critical Control Points: The absence of automated alerts means critical control points may go unmonitored, increasing the risk of contamination events that pose a threat to consumer safety.

By understanding these challenges, food businesses can take proactive steps to improve their compliance management processes and mitigate potential risks.

What Key Features Should a Modern Food Safety Compliance Platform Have?

A modern food safety compliance platform must deliver real-time regulatory updates to keep businesses aligned with constantly evolving food safety laws. These updates automatically notify teams when regulations change, eliminating the risk of operating under outdated standards and preventing compliance gaps that could lead to violations.

Centralized data management transforms how organizations handle food safety information by consolidating all compliance records, test results, inspection reports, and documentation into a single accessible repository. This unified approach ensures quality managers, production staff, and auditors can instantly retrieve critical information without searching through filing cabinets or multiple disconnected systems. The visibility created by centralized storage accelerates decision-making during time-sensitive situations like product recalls or regulatory inspections.

Customizable workflows address the reality that no two food operations function identically. A bakery’s HACCP monitoring procedures differ significantly from a meat processing facility’s requirements. Effective platforms allow businesses to configure:

- Temperature monitoring schedules specific to their products

- Approval chains matching their organizational structure

- Corrective action protocols aligned with their standard operating procedures

- Alert thresholds based on their critical control points

This flexibility ensures the software adapts to existing processes rather than forcing operations to conform to rigid, one-size-fits-all templates that create inefficiencies and user resistance.

How Does Mobile Accessibility Enhance Food Safety Software Usability?

Mobile accessibility transforms compliance management by putting critical food safety tools directly into the hands of frontline workers. Staff can monitor temperatures, document sanitation procedures, and record corrective actions from anywhere in the facility using smartphones or tablets, eliminating the need to return to a central workstation for data entry.

1. On-the-go monitoring

Capabilities mean quality assurance managers can conduct inspections while walking production lines, instantly uploading photos of potential hazards or non-conformances. This immediate documentation creates a real-time compliance record that’s far more accurate than notes transcribed hours later.

2. Instant alerts and notifications

Sent to mobile devices dramatically improve response times when issues arise. A temperature deviation in a cold storage unit triggers immediate notifications to relevant personnel, who can take corrective action within minutes rather than discovering the problem during the next scheduled check.

3. Mobile compliance management

Also supports offline functionality—a critical feature when working in areas with poor connectivity like warehouses or refrigerated spaces. Data syncs automatically once the device reconnects, ensuring no compliance information is lost.

The convenience of mobile access increases staff engagement with food safety protocols. Workers are more likely to complete required checks when they can do so using familiar mobile interfaces rather than navigating complex desktop systems or filling out paper forms.

Why Is Automated Integration Critical in Food Safety Software?

Automated integration eliminates the time-consuming and error-prone process of manually transferring data between systems. When food businesses rely on manual data entry to record test results from laboratory equipment or external testing facilities, the risk of transcription errors increases significantly—potentially leading to incorrect compliance decisions or missed safety issues.

Laboratory Integration

Laboratory integration connects testing devices directly to the compliance platform, automatically capturing results from equipment like pH meters, temperature probes, and microbial testing instruments. This automated data entry ensures accuracy while freeing staff from repetitive documentation tasks.

ERP System Integration

ERP system integration creates a unified view of operations by connecting food safety data with inventory management, production scheduling, and supply chain information. When these systems communicate seamlessly, businesses gain:

- Real-time visibility into ingredient sourcing and lot tracking

- Automatic correlation between production batches and quality test results

- Instant identification of affected products during recall scenarios

- Synchronized documentation across procurement, production, and distribution

The connectivity between laboratory devices, external testing partners, and internal business systems transforms fragmented data points into a comprehensive compliance ecosystem. This integration reduces the administrative burden on quality assurance teams while providing the detailed traceability that regulatory authorities increasingly demand during audits and inspections.

How Can Advanced Reporting Features Reduce Audit Time and Stress for Food Businesses?

Advanced reporting capabilities transform audit preparation from a multi-day scramble into a streamlined process that takes minutes. Fast report creation tools allow food businesses to generate comprehensive documentation instantly when regulators arrive, eliminating the panic of searching through filing cabinets or spreadsheets.

Streamlined Audit Preparation

Modern platforms enable businesses to pull audit reports with a few clicks, automatically compiling data from temperature logs, sanitation records, supplier certifications, and corrective actions into regulator-ready formats. This immediate access to organized information demonstrates professionalism and preparedness during inspections.

Consistency and Completeness

The stress reduction extends beyond speed. Pre-built report templates ensure consistency and completeness, reducing the risk of missing critical information that could trigger violations. Customizable filters let businesses generate reports for specific timeframes, production lines, or compliance areas based on auditor requests.

Proactive Issue Resolution

Real-time data validation within these reporting systems catches discrepancies before auditors do. Automated alerts flag incomplete records or unusual patterns, giving teams time to investigate and address issues proactively rather than explaining gaps during high-pressure inspections.

Flexible Reporting Options

The ability to export reports in multiple formats—PDF, Excel, or CSV—accommodates different regulatory requirements without manual reformatting. Historical report archives provide year-over-year comparisons that demonstrate continuous improvement efforts, a factor that often influences auditor assessments and regulatory relationships.

Moreover, integrating advanced platforms like REDCap can further enhance the efficiency of these reporting processes. The system’s robust functionality allows for sophisticated data management and reporting capabilities that are particularly beneficial in the context of audits1.

How Do Modern Platforms Support Collaboration Among Stakeholders Involved in Food Safety Management?

Modern food safety platforms break down communication barriers by providing collaboration tools that connect everyone involved in the compliance process. These systems enable real-time information sharing between quality assurance teams, production staff, management, suppliers, distributors, and regulatory consultants through a single interface.

Key Features of Modern Food Safety Platforms

The platforms typically include:

- Shared dashboards that give all authorized stakeholders visibility into compliance status, test results, and corrective actions

- Task assignment features that allow managers to delegate responsibilities and track completion across departments

- Comment threads and notification systems that facilitate quick problem-solving when issues arise

- Supplier portals where external partners can submit documentation, certificates, and test results directly into the system

- Role-based access controls ensuring each stakeholder sees relevant information without compromising sensitive data

Benefits of Collaboration Tools in Food Safety Management

When a supplier uploads updated allergen information or a lab reports unexpected test results, the right team members receive instant notifications. This immediate awareness prevents delays in addressing potential safety concerns. The centralized nature of these collaboration tools eliminates the confusion of scattered emails, phone calls, and paper trails that plague traditional systems.

For businesses evaluating options in this Food Safety Software Buyer’s Guide: What to Look for in a Modern Compliance Platform, robust collaboration capabilities should rank as a critical requirement, particularly for organizations managing complex supply chains with multiple locations and partners.

How Are Modern Food Safety Platforms Preparing Businesses for Future Regulations Like The FDA 2026 Rule on Traceability Requirements?

Modern platforms build in scalability features that allow businesses to adapt quickly when new regulations emerge. The FDA 2026 rule requires companies to provide comprehensive traceability data within 24 hours of a request, demanding systems that can capture, store, and retrieve detailed information across the entire supply chain.

Leading food safety software addresses this requirement through:

- Automated data capture at every critical control point, eliminating gaps in the traceability chain

- Lot tracking capabilities that follow ingredients from receiving through production to finished goods

- Digital record-keeping that replaces paper trails with searchable, instantly accessible databases

- Supplier integration tools that connect upstream and downstream partners into a unified traceability network

These platforms use flexible architectures that accommodate new data fields, reporting formats, and compliance requirements without requiring complete system overhauls. Businesses can configure their software to match specific traceability protocols as regulatory bodies release updated guidance.

The scalability extends beyond technical capabilities. Cloud-based solutions grow with business operations, supporting additional facilities, product lines, and markets while maintaining consistent compliance standards. This adaptability proves essential as global food safety requirements continue evolving, with authorities worldwide implementing stricter traceability mandates similar to the FDA’s approach.

What User Experience Features Make Adoption Easier for Food Manufacturers When Implementing A New Compliance Platform?

A user-friendly interface significantly reduces implementation barriers by allowing staff to navigate the system naturally without extensive technical training. Clean, intuitive layouts with logical menu structures enable employees to locate essential functions quickly, cutting onboarding time from weeks to days.

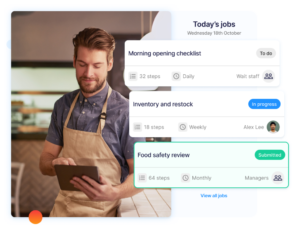

Visual dashboards present critical compliance data through color-coded indicators and graphical representations that communicate status at a glance. Staff members can identify priority tasks, overdue items, and compliance gaps without interpreting complex data tables or navigating multiple screens.

Practical features enhance daily usability:

- Barcode scanning capabilities eliminate manual data entry errors during sample collection and tracking

- Offline access ensures uninterrupted work in production areas with limited connectivity

- Multilingual support accommodates diverse workforces without language barriers

- Role-based permissions display only relevant information to each user, preventing confusion

Contextual help tooltips and embedded guidance provide instant answers to common questions without requiring external documentation. The software anticipates user needs by offering smart suggestions based on previous actions and industry best practices.

Mobile-optimized interfaces mirror desktop functionality, allowing seamless transitions between devices. Staff members familiar with smartphone navigation adapt quickly to the platform’s touch-friendly controls and gesture-based interactions, leveraging existing digital literacy rather than requiring new skill development.

Conclusion

What should guide your final decision when choosing food safety software?

Your unique operational needs should drive the selection process. A modern compliance platform must align with your facility’s size, production complexity, and regulatory requirements. Evaluate vendors based on their ability to deliver real-time regulatory updates, mobile accessibility, and automated integration capabilities that eliminate manual errors.

The right platform grows with your business. Look for solutions that support emerging regulations like the FDA’s 2026 traceability requirements while offering scalable features for expanding operations. Request demonstrations that showcase actual workflows relevant to your industry segment—whether you’re in manufacturing, distribution, or food service.

Consider the total cost of ownership beyond initial licensing fees. Factor in implementation support, ongoing training resources, and system maintenance. Platforms with intuitive interfaces reduce long-term training costs and accelerate staff adoption across shifts and locations.

This Food Safety Software Buyer’s Guide provides the framework for evaluating solutions that protect your brand reputation while streamlining compliance management.

Footnotes

- UNMC REDCap Usage Document

Click here for more Wireless Temperature Monitoring Systems: Are They Worth the Investment in 2025?